What is Sublimation Printing?

The Process

Sublimation printing is another type of garment printing, most directly compared to heat transfer printing. It combines heat and pressure to bond together the dyes and the garment fibers. The sublimation printing process starts with its own printer and inks, similar to DTG prints. However, sublimation printing requires specialized CMYK ink. Set up starts by loading a transfer sheet into the printer, and then designs are printed on the next sheet. Make sure the garment is ready to be printed on (cleaned of dust, wrinkles, etc.), and then apply the transfer paper to the garment. Finish the application by applying heat and pressure from a heat press to solidify the design.

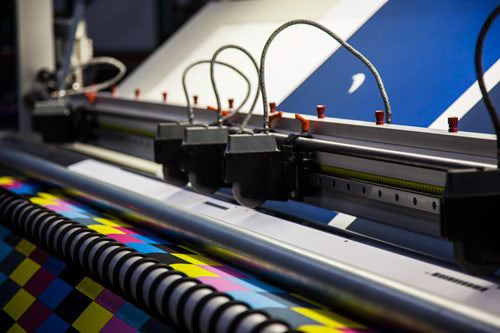

The Technology

While this process is relatively new, there are many different types of sublimation printers to choose from. Some printers prioritize easy-to-use dyes, while others prioritize the print quality itself. The technology mirrors a basic printing process, but what makes this special is the transfer paper - it is a type of paper that can be used with a heat press to transfer designs onto garments. This process requires special inks and a specific sublimation printer to work together.

What’s the Difference Between Sublimation and Heat Transfer?

Many wonder what the key differences are in sublimation vs. heat transfer. Sublimation printing usually has a higher cost than a heat transfer. But when examining the work it produces, more important differences arise. The sublimation printing process incorporates the ink into the garment instead of having the ink rest on top of the garment like in the heat transfer process. Having a layer of ink sit on top can add an extra layer of feel to the garment and not last as long after multiple washes. Depending on the type of heat transfer paper used, one can avoid this issue to a certain degree with higher quality paper. Another difference between the two processes is the type of fabrics it can work on. Sublimation printing only works with polyester fabrics. It also works best on a fabric that is white or light-colored, and the print won’t work as well on a garment that is darker in color. Heat transfer printing does not have this limitation; you can use any type of fabric and any color of fabric and the print will work just as well.

The Pros and Cons of Sublimation Printing

Pros

There are many advantages to sublimation printing if this is the route you choose. It is a simple process and can be easily learned and implemented. It offers an unlimited amount of colors, freedom of design, and the cost remains generally the same regardless of the size. The physical print is not noticeable to the touch, and the process is relatively quick compared to others. So, if your desired fabric is polyester and you choose sublimation printing, it has a lot of advantages to the process.

Cons

The main setback to this process is that it only works on polyester fabrics. It also must have a white or light base on the garment area that plans to be printed on. Even though the ink marries with the fabric, the print can still fade over time, especially when in lots of contact with UV rays. Lastly, just as any printer can have faults, so the ink can jam, and the size of the print is obviously limited to the size of the printer. Deciding on different printing methods can be tedious; understanding both their strengths and weaknesses can help one make the most educated and calculated decisions for their specific business needs.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.